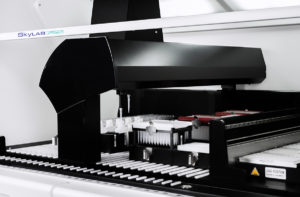

SKYLAB 752

Skylab 752 is an automated ELISA-IFA system able to process up to 500 samples within the same work list.

A fundamental instrument to run large-scale population screening in all the tests required for the research of antibodies developed as immune reaction against a Virus, or to monitor the growth of antibodies after a vaccine.

The applied technologies are composed of new aspiration and dispensation modules, raising precision level by using plastic tips and last generation softwares created to guide the user through the management of the instrument with maximum ease.

DATA SHEET

General Specifications

Incubation Station

Pipetting Station

Washing Station

Reading Station

Other Specifications

Dimensions

General Specifications

General Specifications

| Number of plates | Standard 5+2 |

| Number of IFA slides ** | Standard 28 (7 holders x 4) |

| Sample capacity | Up to 288 primary tubes against 2 tests. Up to 616 primary tubes against 1 test in sample and tips continuous loading mode |

| Continuous sample and tips loading | Yes |

| Sample tube size | Diameter: max 16 mm Height: max 100 mm |

| Number of reagents | From 5 to 40 |

| Number of controls | From 12 to 96 |

| Assays per plate | 2 (in case plates have same coating) |

| Reagent fluid capacity | Up to 60 mL bottles |

| Self-test at start-up | Yes |

Incubation Station

Incubation Station

| Number of incubators | Standard 5+2, with following configuration: 5 independent under plates on the working area and 1 under plate below the working area 1 shaker-incubator unit below the working area 1 to 3 optional extra shaker-incubator units below the working area |

| Temperature range | RT (+ 7°C) to + 50°C |

| Accuracy | ± 1°C |

| Temperature uniformity | ± 1°C |

| Shaking | Yes (optional up 4 plates) 200-1000 rpm |

Pipetting Station

Pipetting Station

| Number of pipettes | 2 independent channels using disposable tips for sample and reagents |

| Sample tip type | Standard disposable tips |

| Sample tip size | 200 -1000 μL |

| Sample pipetting volume | 1 – 200 μL (with large tips up to 1000 μL) |

| Estimated transfer time | < 9 seconds per sample |

| Time to dispense | < 14 minutes (for 96 samples with volume of 100 μL) |

| Precision | Reagents: ≤ 3% CV (10 Replicates) for any operating volume above 25 μL Samples: ≤ 3% CV (10 replicates) for any operating volume above 10 μL |

| Accuracy | Reagents: ± 3% CV (10 replicates) for any operating volume above 25 μL Samples: ± 3% CV (10 replicates) for any operating volume above 10 μL |

| Adding reagent to full 96 plate | From 3 to 7 minutes depending on reagent volume (50 to 200 μL) |

Washing Station

Washing Station

| Manifold configuration | 1 (8-way wash head) |

| Programmable volume | -50 – 2000 μL |

| Residual wash volume | < 3 μL per well in a flat bottom plate |

| Wash containers 6 tanks at 2 liters | 6 tanks at 2.0 L 5 washing buffer + 1 distilled water or washing buffer |

| Buffer level alarm | Yes (with continuous level sensing) |

| Waste container | 8 L with continuous level sensing |

| Dispense precision | ≤5% CV (with 300 pL H2O in 96 well) |

| Liquid level sensing | Gravimetric for all tanks and waste container |

Reading Station

Reading Station

| Photometric range | 0 – 3.3 OD |

| Spectral range | 400 nm to 700 nm |

| Filter slots | 8 |

| Precision | 0.01 SD (at 0.000 to 0.500 OD) ≤ 1% CV (at 0.501 to 2.000 OD) ≤ 1.5% CV (at 2.001 to 2.500 OD) ≤ 5:2.0% CV (at > 2.501 OD) |

| Accuracy | ±0.01 OD or 2.5% (at 0.000 to 3.300 OD) whichever is greater |

| Read time | 5 seconds, single wavelength 8 seconds, dual wavelength |

| Read time | < 5 seconds |

Other Specifications

Other Specifications

| Number of reagent tips | 96 |

| Reagent pipetting volume | Up to 1000 pL |

| Number of sample tips loaded | Up to 9 tip racks (864 in total). No tip number limits in continuous loading mode |

| Dilution Range | 1 part in 200 one stage dilution 1 part in 40000 two stages dilution |

| Direct in-plate predilution | Yes |

| Barcode reader for samples and resources identification | Yes, with capability of reading EAN/ UPC, Code 39, Interleave 2 of 5, Code 93 and Code 128 barcode formats |

Dimensions

Dimensions

| Size | Width 130cm, Depth 94cm, Height 98cm |

| Weight (net) | 220 kg |