competenze chiave

Our first target is to meet demands and needs of our partners by turning them into advanced technological solutions.

We believe the success of our partners to be our best trademark, therefore we put our expertise in automation at the service of those who want to share their goals with us.

We are determined to use our know-how while focusing on the future, with new frontiers being the result of imagination, curiosity and desire to overcome limits. With the right partner, success becomes predictable.

We are sure that ethics, professionalism and curiosity towards alternative solutions are the fundamental ingredients for a successful project. We provide 360-degrees consulting services in terms of trust and collaboration which encourages us to promote the culture of improvement.

We position ourselves as leaders in the development of laboratory diagnostic systems, to turn an idea into robotic automation. Everything is done in order to apply the right solution to a biological sample.

We position ourselves as leaders in the development of laboratory diagnostic systems, to turn an idea into robotic automation. Everything is done in order to apply the right solution to a biological sample.

Our consulting services cover all the application fields to the final product. We analyse market demand proposing a completely automated architecture of the instrument, where needed human support – even if relevant – gets minimised, reducing the risks deriving from the analysis process.

Feasibility study of the product, risk management and investment calculation make us a trustworthy consultant to reach the target.

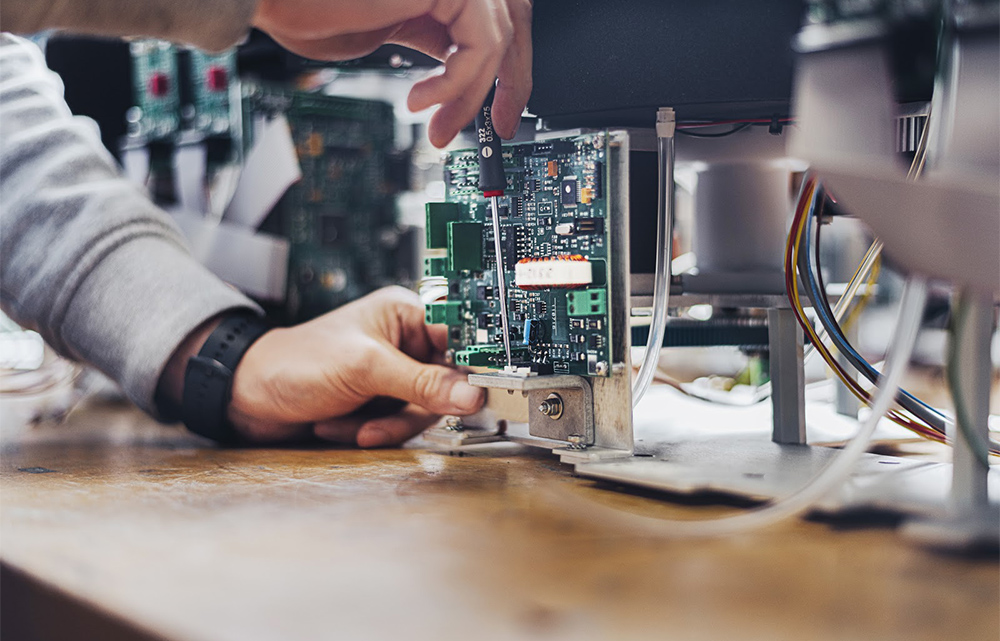

Electronics, different levels of software, mechanics, precision liquid handling, technical documentation for certifications and support in international product registration.

Electronics, different levels of software, mechanics, precision liquid handling, technical documentation for certifications and support in international product registration.

We apply this know-how, required for product development, and lead our partners to the correct choice in order to obtain the aimed result. We dispose of an automation system capable of managing reagents, samples and all the necessary to execute laboratory tests under complete safety and maximum accuracy.

We apply this know-how, required for product development, and lead our partners to the correct choice in order to obtain the aimed result. We dispose of an automation system capable of managing reagents, samples and all the necessary to execute laboratory tests under complete safety and maximum accuracy. Technology and industrial capacity go hand in hand to bring ideas from paper, to computer development systems, and to the prototype development phase.

In our factory we develop constantly evolving production techniques. We have created a laboratory that makes use of the most complete 3D prototyping techniques.

In our factory we develop constantly evolving production techniques. We have created a laboratory that makes use of the most complete 3D prototyping techniques.

Composition of sub-assemblies, final product calibration, colorimetric tests and, soon, also chemical control and validation. These are the skills that we offer to our partners. These are the skills that we offer to our partners.

Part of the production is outsourced to 0 km suppliers, who are carefully selected to ensure the highest quality and professionalism. EVEREX production site is ISO 9001, ISO 13485 and ISO 14000 certified.

We offer the required support for the correct management of the instrument on the market. We provide our partners with service and user educational classes, so that the installation of automated systems and the management of technical assistance is correctly implemented.

We offer the required support for the correct management of the instrument on the market. We provide our partners with service and user educational classes, so that the installation of automated systems and the management of technical assistance is correctly implemented.

In view of a management that allows the machine to daily deliver certain and precise results, correct use and maintenance are crucial to ensure a long lifecycle to the instrument. We offer logistic support to manage all the replacement parts and consumables required for the right functioning of the instrument.